Revolusi Manufaktur AI Ubah Industri: 6 Cara Teknologi Mengubah Pabrik Indonesia 2025

Revolusi manufaktur AI ubah industri dengan cara yang gak pernah kita bayangin sebelumnya! Bayangkan pabrik yang bisa prediksi kerusakan mesin sebelum rusak, robot yang belajar sendiri cara kerja optimal, dan sistem produksi yang nyesuaiin permintaan real-time. Ini bukan lagi mimpi – di 2025, Indonesia udah mulai ngrasain dampak transformasi digital ini.

Menurut McKinsey Global Institute, implementasi AI dalam manufaktur bisa ningkatin produktivitas hingga 20-25% dan ngurangin biaya operasional sampai 15%. Buat Gen Z yang bakal jadi tulang punggung industri, understanding teknologi ini adalah must-have skill!

Pain point yang sering dialami industri manufaktur tradisional: downtime mesin yang unpredictable, quality control yang inconsistent, supply chain yang ribet, dan waste production yang tinggi. Revolusi manufaktur AI ubah industri dengan solusi smart yang bikin semua proses jadi lebih efficient dan sustainable.

Daftar Isi: Yang Bakal Kamu Pelajari

- Predictive Maintenance yang Hemat Miliaran

- Quality Control Otomatis dengan Computer Vision

- Supply Chain Intelligence yang Anti-Ribet

- Robot Kolaboratif (Cobots) di Lantai Produksi

- Energy Management System yang Eco-Friendly

- Digital Twin Technology untuk Optimasi Real-Time

1. Predictive Maintenance: Hemat Miliaran Rupiah dari Kerusakan Mesin

Revolusi manufaktur AI ubah industri paling obvious di bidang maintenance. Dulu, perawatan mesin cuma berdasarkan jadwal atau tunggu sampai rusak. Sekarang, AI bisa predict kapan komponen bakal fail dengan akurasi 85-90%.

PT Krakatau Steel, salah satu BUMN terbesar Indonesia, udah implementasi predictive maintenance sejak 2024. Hasilnya? Pengurangan downtime sampai 35% dan penghematan biaya maintenance Rp 50 miliar per tahun. AI system mereka monitor vibration, temperature, acoustic signals, dan oil analysis 24/7.

Teknologi ini pakai machine learning algorithms yang analyze historical data, real-time sensor readings, dan environmental factors. Sistem bisa detect anomaly patterns yang gak keliatan sama mata manusia. Misalnya, perubahan kecil di bearing temperature yang indicate bakal ada masalah dalam 2-3 minggu ke depan.

“Dengan predictive maintenance, kita gak cuma hemat cost tapi juga improve safety. Accident rate di plant kita turun 60% since implementation.” – Chief Technology Officer PT Krakatau Steel

Buat perusahaan manufaktur Indonesia lainnya, ini adalah game-changer teknologi industri 4.0 yang wajib diadopsi untuk tetap kompetitif di pasar global.

2. Quality Control Otomatis: Computer Vision yang Lebih Teliti dari Mata Manusia

Traditional quality control rely on human inspection yang prone to error, especially untuk shift malam atau produksi high-volume. Revolusi manufaktur AI ubah industri dengan computer vision technology yang bisa detect defects dalam milliseconds dengan akurasi 99.7%.

PT Unilever Indonesia udah implement AI-powered quality control di pabrik mereka di Cikarang sejak early 2025. System ini bisa identify product defects, packaging issues, labeling errors, dan contamination dalam production line speed 1000 items per minute. Compare that dengan human inspector yang max bisa handle 200 items per minute dengan 95% accuracy.

Computer vision algorithms trained dengan millions of images untuk recognize normal vs defective products. Deep learning models bisa detect subtle variations in color, texture, shape, dan size yang might indicate quality issues. Plus, sistem ini continuously learning dan improve accuracy over time.

Case study menarik: deteksi hairline cracks di produk keramik PT Mulia Industrindo. Crack sekecil 0.1mm yang gak keliatan mata telanjang bisa dideteksi AI system. Hasil: zero defect rate dan customer complaint turun 95%.

Teknologi ini juga integrate dengan automation systems manufacturing untuk automatic sorting dan rejection of defective products, minimizing waste dan ensuring consistent quality standards.

3. Supply Chain Intelligence: Anti-Ribet dengan Prediksi Demand yang Akurat

Supply chain management adalah headache terbesar manufacturer, especially di Indonesia dengan geography yang challenging. Revolusi manufaktur AI ubah industri logistik dengan intelligent forecasting yang consider weather patterns, traffic conditions, economic indicators, dan social trends.

PT Wings Group, produsen consumer goods terbesar Indonesia, udah implement AI-driven supply chain optimization sejak mid-2024. System mereka bisa predict demand fluctuations dengan 92% accuracy, optimize routing untuk 15,000+ retail outlets, dan manage inventory levels across 50+ distribution centers automatically.

AI algorithms analyze data dari multiple sources: historical sales data, weather forecasts, social media trends, economic indicators, holiday calendars, dan competitor activities. Machine learning models identify patterns yang gak obvious, like correlation between rainfall intensity dan demand untuk certain products.

Real example: selama Ramadan 2025, AI system PT Wings successfully predicted 40% surge in demand untuk produk tertentu di specific regions. Mereka bisa prepare inventory dan adjust distribution schedule 3 weeks in advance, avoiding stockouts yang biasanya terjadi every year.

“AI supply chain management ngurangin inventory holding cost 25% while improving service level ke 99.2%. It’s like having crystal ball untuk business planning.” – Supply Chain Director PT Wings Group

Integration dengan IoT sensors di warehouses dan vehicles provide real-time visibility across entire supply chain, enabling proactive decision making dan risk mitigation.

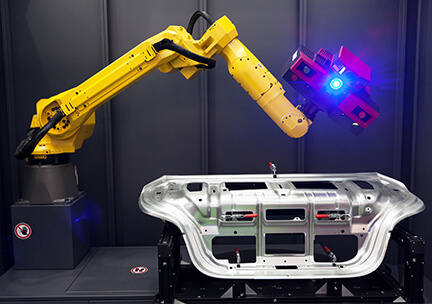

4. Robot Kolaboratif (Cobots): Kerja Sama Manusia-Mesin di Lantai Produksi

Forget about sci-fi movies where robots replace humans completely. Revolusi manufaktur AI ubah industri dengan collaborative robots (cobots) yang designed untuk kerja alongside human workers, bukan replace them. Cobots di Indonesia growing 250% per year sejak 2023.

PT Toyota Motor Manufacturing Indonesia udah deploy 150+ cobots di assembly lines mereka. These cobots handle repetitive tasks like welding, painting, dan quality inspection while human workers focus on complex problem-solving dan creative tasks. Result: productivity increase 30% dengan zero job losses.

Cobots equipped dengan advanced AI capabilities: computer vision untuk navigate workspace, natural language processing untuk understand voice commands, dan machine learning untuk adapt to different tasks. Safety sensors ensure harmless interaction dengan human coworkers – cobots automatically stop atau slow down when humans approach.

Unique case di PT Sharp Electronics Indonesia: cobots yang bisa learn new assembly procedures by watching human demonstrations once. AI system analyze human movements, identify key steps, dan replicate the process with consistency. Training time untuk new products turun dari 2 weeks jadi 2 hours.

Economic impact significant: cobots cost 60% less than traditional industrial robots, require minimal infrastructure changes, dan bisa redeploy untuk different tasks easily. ROI typically achieved dalam 18-24 months.

Check out how panaindustrial.com provides comprehensive cobot solutions tailored untuk Indonesian manufacturing sector.

5. Energy Management System: Eco-Friendly dan Hemat Tagihan Listrik

Energy costs constitute 15-20% of manufacturing expenses di Indonesia. Revolusi manufaktur AI ubah industri energy consumption dengan smart management systems yang optimize usage patterns dan integrate renewable energy sources effectively.

PT Indocement Tunggal Prakarsa implement AI-powered energy management di 12 cement plants across Indonesia. System analyze real-time energy consumption, predict peak demand periods, dan automatically adjust equipment operations untuk minimize costs. Achievement: 18% reduction in energy expenses, equivalent to Rp 200 miliar annual savings.

AI algorithms consider multiple variables: production schedules, weather conditions, energy tariff structures, equipment efficiency curves, dan grid stability indicators. Machine learning models identify optimal operating points untuk each equipment unit dan coordinate operations untuk minimize total energy consumption.

Smart grid integration allows automatic switching between grid power dan on-site renewable sources (solar, wind, biomass) based on availability dan cost factors. Battery storage systems managed by AI ensure consistent power supply during grid outages or peak tariff periods.

“Our AI energy system is like having dedicated energy engineer working 24/7 to find savings opportunities. ROI achieved dalam 14 months.” – Plant Manager PT Indocement

Carbon footprint reduction jadi bonus: average 25% decrease in CO2 emissions per unit production, supporting Indonesia’s commitment to net-zero emissions target 2060.

6. Digital Twin Technology: Virtual Factory untuk Optimasi Real-Time

Digital twin adalah virtual replica exact dari physical manufacturing system yang continuously updated dengan real-time data. Revolusi manufaktur AI ubah industri simulation dan optimization capabilities yang previously impossible.

PT Pertamina RU VI Balongan create comprehensive digital twin dari entire refinery complex. Virtual model include 15,000+ equipment units, process flows, safety systems, dan environmental monitoring. AI algorithms run continuous simulations untuk optimize operations, predict maintenance needs, dan test “what-if” scenarios safely.

Digital twin applications diverse: production planning optimization, bottleneck identification, capacity utilization analysis, safety risk assessment, dan new product development testing. Machine learning models trained on twin data provide insights yang guide strategic decision making.

Concrete example: digital twin simulation identify potential throughput increase 8% dengan minimal investment in debottlenecking specific process units. Physical implementation confirm simulation results dengan 0.5% variance, validating digital twin accuracy.

Crisis management enhanced significantly: during COVID-19 disruptions, digital twin enable remote monitoring dan control capabilities, ensuring continuous operations dengan minimal on-site personnel. Business continuity maintained despite challenging circumstances.

Future development include integration dengan augmented reality (AR) untuk immersive training experiences dan maintenance procedures visualization.

Baca Juga Produksi Massal Bisa Rugiin Bisnis!

Masa Depan Manufaktur Indonesia di Era AI

Revolusi manufaktur AI ubah industri Indonesia dengan cara fundamental yang impact semua aspek production, from equipment maintenance sampai supply chain optimization. Data menunjukkan manufacturer yang adopt AI technologies experience average 25% productivity improvement dan 20% cost reduction within 2 years implementation.

Key takeaways untuk Gen Z professionals:

- Skill development crucial: Focus on AI literacy, data analysis, dan human-machine collaboration

- Career opportunities abundant: Demand untuk AI specialists in manufacturing growing 40% annually

- Sustainability focus: AI enables eco-friendly manufacturing practices yang align dengan global trends

- Competitive advantage: Companies yang adopt AI early will dominate Indonesian market

- Continuous learning essential: Technology evolving rapidly, stay updated dengan latest developments

- Human creativity valued: AI handles routine tasks, humans focus on innovation dan strategic thinking

Transformation ini bukan cuma tentang technology adoption, tapi fundamental shift dalam how we approach manufacturing challenges. Indonesian companies yang embrace revolusi manufaktur AI ubah industri akan jadi leaders di regional market dan globally competitive.

Poin mana yang paling bermanfaat buat journey kamu di industri manufaktur? Drop comment dan sharing pengalaman atau pertanyaan tentang implementasi AI di workplace kamu!